HollyFrontier Specialty Products' Sunpar oils are highly refined, premium quality oils designed for a wide variety of rubber applications. Most of these oils are ASTM Type 104 oils. Structurally, they have a predominance of saturated rings and long paraffinic side chains containing a minimum of 55% paraffinic carbon atoms (Cp) and thus are highly saturated. Because they are designed for the rubber industry, they are intended to offer rubber compounders a balance of compatibility, processability, color stability, reduced peroxide consumption, and low sulfur contents. Compared to naphthenic and aromatic oils, they are generally more resistant to oxidation and color degradation from ultraviolet light and heat. Sunpar oils find applications in both thermoset and thermoplastic rubbers.

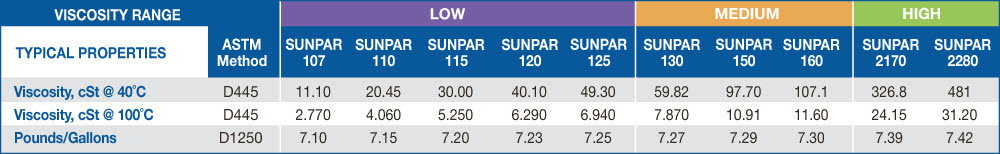

(Click image to enlarge)

Thermoset Elastomers

The Sunpar grades are excellent choices for use with thermoset elastomers such as IIR, EPM, EPDM, IR, NR in either sulfur or peroxide cures. They are highly recommended for applications requiring low odor, good initial color, and color stability to heat and light.

Thermoplastic Elastomers

The Sunpar grades are also excellent choices for use with thermoplastic elastomers such as SBS, SEBS, or TPVs. They offer the thermoplastic producer a balance of compatibility, improved processability, colorability, and low volatiles.

OSHA Status and IP 346

Sunpar oils do not require labeling as potential dermal carcinogens under the OSHA Hazard Communication Standard. They also comply with IP 346, producing less than 3 wt% DMSO extractables. This criteria is based upon European Commission Directive 94/69 EC, 21st Adaptation for coal and oil derived products. It stipulates that the classification as a carcinogen need not apply if it can be shown that the substance contains less than 3 wt% DMSO extractables as measured by IP 346.

Aromatic Content

The lower aromatic content of Sunpar 2280 is particularly significant in peroxide cured applications where it can reduce the curative loading and, therefore, the cost of the expensive peroxide curative. The accompanying chart, Peroxide Loading Vs.Total Aromatics, illustrates how the lower aromatic content of Sunpar 2280 can reduce peroxide loading by 1 phr (parts per hundred). The benefits of the lower aromatic content paraffinic oils are discussed in detail in our publication, “Petroleum Extender Oils for Reduced Peroxide Consumption in Compounded EPDM”. Using Sunpar 2280 at nominally 24% aromatics in a selected recipe provides an effective level of aromatics of 6% when all the compounding ingredients are considered. Using a competitive oil containing a higher percentage of aromatics imparts an effective level of 10% aromatics. Achieving the same net torque would require increasing the peroxide loading by 1 phr, from 2 to 3 phr.

Sunpar Paraffinic Oils exhibit excellent color stability and low volatility. Their low aromatic content makes them excellent choices in peroxide cures where aromatics interfere with the curing process. Compared to inferior oils, you can:

- Obtain less oxidative and color degradation

- Lower emissions during mixing and cures

- Obtain better heat aging

- Reduce peroxide consumption

- Obtain longer service life with Sunpar oils

Click the links below to download Sunpar SDS (PDF format):

- Sunpar 107

- Sunpar 110

- Sunpar 115

- Sunpar 120

- Sunpar 125

- Sunpar 130

- Sunpar 150

- Sunpar 160

- Sunpar 2170

- Sunpar 2280

▶ Can't find an SDS? Visit our SDS section or call us at 1.800.456.4786