HollyFrontier Specialty Products' Sundex aromatic rubber process oils provide outstanding performance through their consistently high quality and unique properties. HollyFrontier Specialty Products is more selective in its refinery process than many other producers of aromatic oils who consider their oils as by-products. HollyFrontier Specialty Products use a solvent refining process and additional proprietary steps to extract the aromatics rather than distillation alone.

The Sundex oils have distinctly better properties than competitive extracts and thereby offer the rubber industry several compounding advantages. The higher aromatic levels (low aniline points) of Sundex oils yield maximum loading potential and reduced mixing times through increased polymer compatibility. The low wax levels reduce "blooming" and "building tack" problems in tire assembly. Additionally, Sundex oils low volatility reduces smoking and volatile losses in the curing and mixing processes.

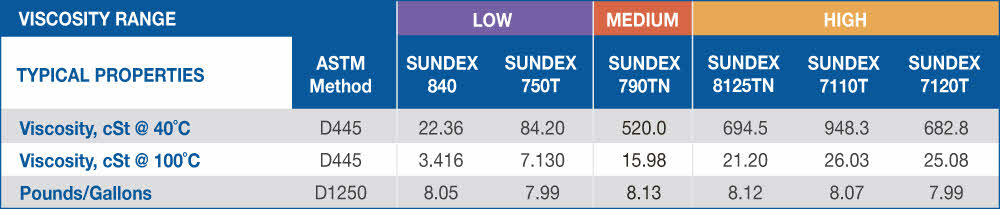

(Click image to enlarge)

- Sundex Aromatic Oils exhibit a high aromatic content, higher extender index and low wax content. Compared to inferior oils, your benefits include:

- Higher oil loadings

- Lower pound/volume cost

- Faster mixing times, higher yields

- Better carbon black dispersion

- Higher aromatic content may offer both the polymer manufacturer and the rubber compounder more reliability and latitude to increase oil loading without unacceptable oil bleed out. Since there is generally nothing less expensive in most rubber recipes than process oil for both the polymer and rubber compounder alike, the higher aromatic content helps reduce the pound/volume cost.

- For the rubber compounder, the higher aromatic content also helps promote faster mixing by improving take-up time and therefore, helps to increase the number of Banbury® batches per 8-hour shift and, accordingly, greater productivity. Faster mixing times also translate into lower power consumption per batch. For many polymer systems, an oil with higher aromatic content imparts better carbon black dispersion and, therefore, helps to achieve better product consistency for statistical process control. Our publication, "Effect of Rubber Processing Oils on the Dispersion of Carbon Black in SBR," discusses this in detail. It concludes that carbon black dispersion increases as the aromatic content of the oil increases, and that, in general, physical properties improve as the degree of dispersion increases.

Click the links below to download Sundex SDS (PDF format):

▶ Can't find an SDS? Visit our SDS section or call us at 1.800.456.4786